PCB has developed from single layers to double-sided, multi-layer and flexible, and still maintain their respective development trends. Due to the continuous development of high precision, high density and high reliability, Constantly shrinking size, reducing costs and improving performance, so that the printed board still maintains a strong vitality in the development of electronic equipment in the future.

So how is PCB layout designed? After reading the following seven steps, you will understand it.

1.PCB Design Preparation Work

It includes preparation of component libraries and schematics. Before PCB layout design, We need to prepare the schematic SCH component library and PCB component package library firstly.

The PCB component package library is preferably built by the engineer based on the standard size data of the selected device. In principle, the first thing you did was build the component package library of the PC, and then build the Schematic SCH component library.

The PCB component package library has higher requirements, which directly affects the PCB installation.However, Schematic SCH component library requirements are relatively loose, but pay attention to define the pin attributes and the corresponding relationship with the PCB component package library.

2.PCB Structural Design

Draw a PCB frame in the PCB design environment based on the determined board size and various mechanical positioning.

Fully consider and determine the wiring area and non-wiring area (such as the extent of the screw hole is a non-wiring area).

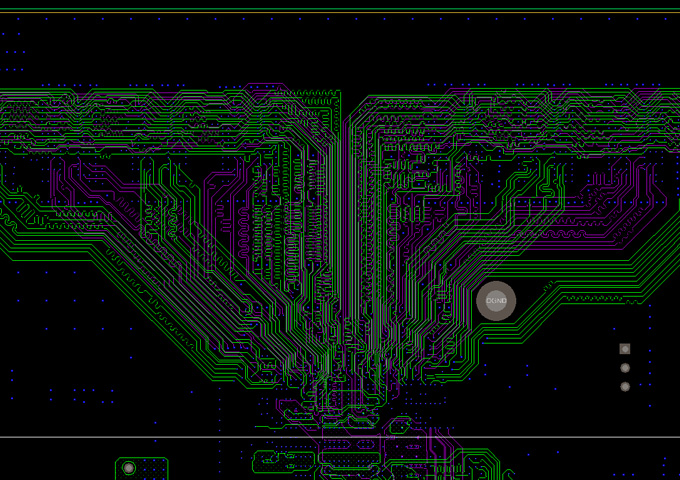

3.PCB Layout Design Ⅰ

The layout design is to place the device in the PCB frame according to the design requirements.We need to generate a netlist in the schematic tool (Design→Create Netlist), Then import the network table (Design→Import Netlist) in the PCB software. After the network table is successfully imported, it will exist in the software background. All devices can be taken and fly-wire prompt connection between each pin by the Placement operation. and the device can be laid out.

PCB layout design is the first important process in the entire PCB design process. The more complicated the PCB board, the better the layout can affect the ease of implementation of post-wiring. Whether the layout is good or bad can directly affect the ease of implementation of post-wiring.

Layout design relies on the circuit board designer’s circuit foundation and design experience, which is a high level requirement for circuit board designers. The primary circuit board designer has a light experience, suitable for small module layout design or PCB layout design tasks with low board difficulty.

4.PCB Layout Design Ⅱ

PCB layout design is the most labor-intensive process in the overall PCB design, directly affecting the performance of PCB.

The first thing is do Layout connection, which is the most basic entry requirement for PCB Design.

Secondly,Satisfaction of electrical performance, which is a measure of the eligibility of PCB board After the line is laid, we need to carefully adjust the wiring to achieve the best electrical performance.

At Last, it must be neat and beautiful. Disorganized wiring, even if the electrical performance is passed, it will bring great inconvenience to the later optimization and maintenance. So the wiring requirements must be in accordance with design specifications

5.Wiring optimization and silk screen placement

“PCB design is not the best, only better”, “PCB design is the art of a defect”, mainly because PCB design has to meet the design needs of all aspects of hardware, and individual requirements may be conflicting.

For example, Some PCB design project needs to be designed into a 6-layer board after evaluation by electronic board designer. However, Product hardware engineers require that it must be designed as 4-layer boards for cost consideration, then only the signal shielding ground layer can be sacrificed, resulting in an increase in signal crosstalk between adjacent wiring layers and decrease in signal quality.

The general design experience is that the time of optimize the wiring is twice the time of the initial wiring. After the PCB layout optimization is completed, post-processing is required. The first thing to deal with is the silk screen mark on the PCB board surface. The bottom screen silk screen characters need to be mirrored during design to avoid confusion with the top screen printing.

6.Network DRC inspection and structural inspection

Quality control is an important part of the PCB design process. The general quality control methods include: design self-inspection, design mutual inspection, expert review meeting, special inspection, etc.

The schematic and structural element diagrams are the most basic design requirements. The network DRC inspection and structural inspection are to confirm that the PCB design meets the two input conditions of the schematic netlist and the structural element diagram.

In General, Electronic board designer will have their own accumulated design quality checklists, some of which are derived from the specifications of the company or department, and others from their own experience. Special inspections include Valor inspection and DFM inspection of the design. These two parts focus on the PCB design output back-end processing lithography files.

7.PCB Fabrication

The last one is also very important. Before the PCB is formally processed, electronic board designer needs to communicate with the PE of the PCB board supplier, to answer the manufacturer’s confirmation about PCB board processing.

This includes but is not limited to, PCB board model selection, line layer’s width and spacing adjustment, impedance control adjustment, PCB laminate thickness adjustment, surface treatment process, hole size tolerance control and delivery standards.

The above is the entire process of PCB design.